Renewable Design for U Bolts - ASME B18.2.1 UNC Hex Bolt Grade 5 Black Oxide Inch Size 1/2-13 – Hongji

Renewable Design for U Bolts - ASME B18.2.1 UNC Hex Bolt Grade 5 Black Oxide Inch Size 1/2-13 – Hongji

Renewable Design for U Bolts - ASME B18.2.1 UNC Hex Bolt Grade 5 Black Oxide Inch Size 1/2-13 – Hongji Detail:

Description

QUICK Response

QUICK Quotation

QUICK Delivery

READY TO SHIP DELIVERY

10000+ SKU in warehouse

We Commit for RTS items:

70% items delivered within 5 days

80% items delivered within 7 days

90% items delivered within 10 days

Bulk orders, please contact customer service

Please contact us for more information, such as the weight, the packing specification, the price list, and so on.

|

Dia/d |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

5/8 |

3/4 |

7/8 |

1 |

1-1/8 |

1-1/4 |

1-3/8 |

1-1/2 |

|

|

PP |

UNC |

20 |

18 |

16 |

14 |

13 |

11 |

10 |

9 |

8 |

7 |

7 |

6 |

6 |

|

UNF |

28 |

24 |

24 |

20 |

20 |

18 |

16 |

14 |

12 |

12 |

12 |

12 |

12 |

|

|

8-UN |

- |

- |

- |

- |

- |

- |

- |

- |

- |

8 |

8 |

8 |

8 |

|

|

ds |

max |

0.26 |

0.324 |

0.388 |

0.452 |

0.515 |

0.642 |

0.768 |

0.895 |

1.022 |

1.149 |

1.277 |

1.404 |

1.531 |

|

min |

0.237 |

0.298 |

0.36 |

0.421 |

0.482 |

0.605 |

0.729 |

0.852 |

0.976 |

1.098 |

1.223 |

1.345 |

1.47 |

|

|

s |

max |

0.438 |

0.5 |

0.562 |

0.625 |

0.75 |

0.938 |

1.125 |

1.312 |

1.5 |

1.688 |

1.875 |

2.062 |

2.25 |

|

min |

0.425 |

0.484 |

0.544 |

0.603 |

0.725 |

0.906 |

1.088 |

1.269 |

1.45 |

1.631 |

1.812 |

1.994 |

2.175 |

|

|

e |

max |

0.505 |

0.577 |

0.65 |

0.722 |

0.866 |

1.083 |

1.299 |

1.516 |

1.732 |

1.949 |

2.165 |

2.382 |

2.598 |

|

min |

0.484 |

0.552 |

0.62 |

0.687 |

0.826 |

1.033 |

1.24 |

1.447 |

1.653 |

1.859 |

2.066 |

2.273 |

2.48 |

|

|

k |

max |

0.188 |

0.235 |

0.268 |

0.316 |

0.364 |

0.444 |

0.524 |

0.604 |

0.7 |

0.78 |

0.876 |

0.94 |

1.036 |

|

min |

0.15 |

0.195 |

0.226 |

0.272 |

0.302 |

0.378 |

0.455 |

0.531 |

0.591 |

0.658 |

0.749 |

0.81 |

0.902 |

|

|

r |

max |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.06 |

0.06 |

0.06 |

0.09 |

0.09 |

0.09 |

0.09 |

0.09 |

|

min |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.02 |

0.02 |

0.02 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

|

|

b |

L≤6 |

0.75 |

0.875 |

1 |

1.125 |

1.25 |

1.5 |

1.75 |

2 |

2.25 |

2.5 |

2.75 |

3 |

3.25 |

|

L>6 |

1 |

1.125 |

1.25 |

1.375 |

1.5 |

1.75 |

2 |

2.25 |

2.5 |

2.75 |

3 |

3.25 |

3.5 |

|

|

Dia/d |

1-5/8 |

1-3/4 |

1-7/8 |

2 |

2-1/4 |

2-1/2 |

2-3/4 |

3 |

3-1/4 |

3-1/2 |

3-3/4 |

4 |

|

|

PP |

UNC |

- |

5 |

- |

4-1/2 |

4-1/2 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

|

UNF |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

8-UN |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

|

|

ds |

max |

1.658 |

1.785 |

1.912 |

2.039 |

2.305 |

2.559 |

2.827 |

3.081 |

3.335 |

3.589 |

3.858 |

4.111 |

|

min |

1.591 |

1.716 |

1.839 |

1.964 |

2.214 |

2.461 |

2.711 |

2.961 |

3.21 |

3.461 |

3.726 |

3.975 |

|

|

s |

max |

2.438 |

2.625 |

2.812 |

3 |

3.375 |

3.75 |

4.125 |

4.5 |

4.875 |

5.25 |

5.625 |

6 |

|

min |

2.356 |

2.538 |

2.719 |

2.9 |

3.262 |

3.625 |

3.988 |

4.35 |

4.712 |

5.075 |

5.437 |

5.8 |

|

|

e |

max |

2.815 |

3.031 |

3.248 |

3.464 |

3.897 |

4.33 |

4.763 |

5.196 |

5.629 |

6.062 |

6.495 |

6.928 |

|

min |

2.616 |

2.893 |

3.099 |

3.306 |

3.719 |

4.133 |

4.546 |

4.959 |

5.372 |

5.786 |

6.198 |

6.612 |

|

|

k |

max |

1.116 |

1.196 |

1.276 |

1.388 |

1.548 |

1.708 |

1.869 |

2.06 |

2.251 |

2.38 |

2.572 |

2.764 |

|

min |

0.978 |

1.054 |

1.13 |

1.175 |

1.327 |

1.479 |

1.632 |

1.815 |

1.936 |

2.057 |

2.241 |

2.424 |

|

|

r |

max |

0.09 |

0.12 |

0.12 |

0.12 |

0.19 |

0.19 |

0.19 |

0.19 |

0.19 |

0.19 |

0.19 |

0.19 |

|

min |

0.03 |

0.04 |

0.04 |

0.04 |

0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

|

|

b |

L≤6 |

3.5 |

3.75 |

4 |

4.25 |

4.75 |

5.25 |

5.75 |

6.25 |

6.75 |

7.25 |

7.75 |

8.25 |

|

L>6 |

3.75 |

4 |

4.25 |

4.5 |

5 |

5.5 |

6 |

6.5 |

7 |

7.5 |

8 |

8.5 |

|

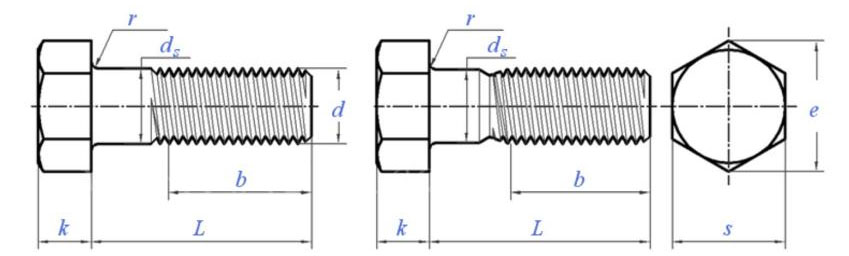

Detail drawing

What does the “UNC” meaning?

UNC refers to the coarse thread in the United States unified thread UN series (optional external thread root radius).

What”s the Black Oxide surface treatment?

Black oxide, a common means of chemical surface treatment. Black oxide is a common method of chemical surface treatment. The principle is to produce an oxide film on the metal surface to isolate the air and achieve the purpose of rust prevention. When the appearance requirements are not high, blackening can be used, and the surface of steel parts is blackened, which is also called blue.

The commonly used methods of black oxide treatment include traditional alkaline heating blackening and room temperature blackening which occurs later. However, the blackening process at room temperature is not very effective for low carbon steel. Alkaline blackening is subdivided, and there is a difference between once blackening and twice blackening. The main components of blackening liquid are sodium hydroxide and sodium nitrite. The temperature difference required for blackening is not large, and a good surface can be obtained between 135-155 °C, but the time required is a little long.

Packing

About us

* The following diagram identifies the different trade incoterms. Please select the one you prefer.

Product detail pictures:

Related Product Guide:

With our loaded working experience and thoughtful products and services, we've got been acknowledged as a reputable supplier for most international buyers for Renewable Design for U Bolts - ASME B18.2.1 UNC Hex Bolt Grade 5 Black Oxide Inch Size 1/2-13 – Hongji , The product will supply to all over the world, such as: Rome, Mongolia, UK, With the advanced workshop, professional design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our products are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed