OEM Manufacturer Fully Threaded Bolts - HDG DIN933 Hex Head Bolt Hot Dipped Galvanized – Hongji

OEM Manufacturer Fully Threaded Bolts - HDG DIN933 Hex Head Bolt Hot Dipped Galvanized – Hongji

OEM Manufacturer Fully Threaded Bolts - HDG DIN933 Hex Head Bolt Hot Dipped Galvanized – Hongji Detail:

Description

QUICK Response

QUICK Quotation

QUICK Delivery

READY TO SHIP DELIVERY

10000+ SKU in warehouse

We Commit for RTS items:

70% items delivered within 5 days

80% items delivered within 7 days

90% items delivered within 10 days

Bulk orders, please contact customer service

|

d |

M1.6 |

M2 |

M2.5 |

M3 |

(M3.5) |

M4 |

M5 |

M6 |

(M7) |

M8 |

M10 |

M12 |

(M14) |

M16 |

|||||||||||||||||

|

P |

Pitch |

0.35 |

0.4 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2 |

||||||||||||||||

|

a |

Max |

1.05 |

1.2 |

1.35 |

1.5 |

1.8 |

2.1 |

2.4 |

3 |

3 |

3.75 |

4.5 |

5.25 |

6 |

6 |

||||||||||||||||

|

c |

Min |

0.1 |

0.1 |

0.1 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.2 |

||||||||||||||||

|

Max |

0.25 |

0.25 |

0.25 |

0.4 |

0.4 |

0.4 |

0.5 |

0.5 |

0.5 |

0.6 |

0.6 |

0.6 |

0.6 |

0.8 |

|||||||||||||||||

|

da |

Max |

2 |

2.6 |

3.1 |

3.6 |

4.1 |

4.7 |

5.7 |

6.8 |

7.8 |

9.2 |

11.2 |

13.7 |

15.7 |

17.7 |

||||||||||||||||

|

dw |

A Class |

Min |

2.4 |

3.2 |

4.1 |

4.6 |

5.1 |

5.9 |

6.9 |

8.9 |

9.6 |

11.6 |

15.6 |

17.4 |

20.5 |

22.5 |

|||||||||||||||

|

B Class |

Min |

- |

- |

- |

- |

- |

5.7 |

6.7 |

8.7 |

9.4 |

11.4 |

15.4 |

17.2 |

20.1 |

22 |

||||||||||||||||

|

e |

A Class |

Min |

3.41 |

4.32 |

5.45 |

6.01 |

6.58 |

7.66 |

8.79 |

11.05 |

12.12 |

14.38 |

18.9 |

21.1 |

24.49 |

26.75 |

|||||||||||||||

|

B Class |

Min |

- |

- |

- |

- |

- |

7.5 |

8.63 |

10.89 |

11.94 |

14.2 |

18.72 |

20.88 |

23.91 |

26.17 |

||||||||||||||||

|

k |

Nominal |

1.1 |

1.4 |

1.7 |

2 |

2.4 |

2.8 |

3.5 |

4 |

4.8 |

5.3 |

6.4 |

7.5 |

8.8 |

10 |

||||||||||||||||

|

A Class |

Min |

0.98 |

1.28 |

1.58 |

1.88 |

2.28 |

2.68 |

3.35 |

3.85 |

4.65 |

5.15 |

6.22 |

7.32 |

8.62 |

9.82 |

||||||||||||||||

|

Max |

1.22 |

1.52 |

1.82 |

2.12 |

2.52 |

2.92 |

3.65 |

4.15 |

4.95 |

5.45 |

6.56 |

7.68 |

8.98 |

10.18 |

|||||||||||||||||

|

B Class |

Min |

- |

- |

- |

- |

- |

2.6 |

3.26 |

3.76 |

4.56 |

5.06 |

6.11 |

7.21 |

8.51 |

9.71 |

||||||||||||||||

|

Max |

- |

- |

- |

- |

- |

3 |

3.74 |

4.24 |

5.04 |

5.54 |

6.69 |

7.79 |

9.09 |

10.29 |

|||||||||||||||||

|

k1 |

Min |

0.7 |

0.9 |

1.1 |

1.3 |

1.6 |

1.9 |

2.28 |

2.63 |

3.19 |

3.54 |

4.28 |

5.05 |

5.96 |

6.8 |

||||||||||||||||

|

r |

Min |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.2 |

0.2 |

0.25 |

0.25 |

0.4 |

0.4 |

0.6 |

0.6 |

0.6 |

||||||||||||||||

|

s |

Max=Nominal |

3.2 |

4 |

5 |

5.5 |

6 |

7 |

8 |

10 |

11 |

13 |

17 |

19 |

22 |

24 |

||||||||||||||||

|

A Class |

Min |

3.02 |

3.82 |

4.82 |

5.32 |

5.82 |

6.78 |

7.78 |

9.78 |

10.73 |

12.73 |

16.73 |

18.67 |

21.67 |

23.67 |

||||||||||||||||

|

B Class |

Min |

- |

- |

- |

- |

- |

6.64 |

7.64 |

9.64 |

10.57 |

12.57 |

16.57 |

18.48 |

21.16 |

23.16 |

||||||||||||||||

|

d |

(M18) |

M20 |

(M22) |

M24 |

(M27) |

M30 |

(M33) |

M36 |

(M39) |

M42 |

(M45) |

M48 |

(M52) |

||||||||||||||||||

|

P |

Pitch |

2.5 |

2.5 |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4 |

4.5 |

4.5 |

5 |

5 |

|||||||||||||||||

|

a |

Max |

7.5 |

7.5 |

7.5 |

9 |

9 |

10.5 |

10.5 |

12 |

12 |

13.5 |

13.5 |

15 |

15 |

|||||||||||||||||

|

c |

Min |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

|||||||||||||||||

|

Max |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

1 |

1 |

1 |

1 |

1 |

||||||||||||||||||

|

da |

Max |

20.2 |

22.4 |

24.4 |

26.4 |

30.4 |

33.4 |

36.4 |

39.4 |

42.4 |

45.6 |

48.6 |

52.6 |

56.6 |

|||||||||||||||||

|

dw |

A Class |

Min |

25.3 |

28.2 |

30 |

33.6 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||||||

|

B Class |

Min |

24.8 |

27.7 |

29.5 |

33.2 |

38 |

42.7 |

46.5 |

51.1 |

55.9 |

59.9 |

64.7 |

69.4 |

74.2 |

|||||||||||||||||

|

e |

A Class |

Min |

30.14 |

33.53 |

35.72 |

39.98 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||||||

|

B Class |

Min |

29.56 |

32.95 |

35.03 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

71.3 |

76.95 |

82.6 |

88.25 |

|||||||||||||||||

|

k |

Nominal |

11.5 |

12.5 |

14 |

15 |

17 |

18.7 |

21 |

22.5 |

25 |

26 |

28 |

30 |

33 |

|||||||||||||||||

|

A Class |

Min |

11.28 |

12.28 |

13.78 |

14.78 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|||||||||||||||||

|

Max |

11.72 |

12.72 |

14.22 |

15.22 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||||||||

|

B Class |

Min |

11.15 |

12.15 |

13.65 |

14.65 |

16.65 |

18.28 |

20.58 |

22.08 |

24.58 |

25.58 |

27.58 |

29.58 |

32.5 |

|||||||||||||||||

|

Max |

11.85 |

12.85 |

14.35 |

15.35 |

17.35 |

19.12 |

21.42 |

22.92 |

25.42 |

26.42 |

28.42 |

30.42 |

33.5 |

||||||||||||||||||

|

k1 |

Min |

7.8 |

8.5 |

9.6 |

10.3 |

11.7 |

12.8 |

14.4 |

15.5 |

17.2 |

17.9 |

19.3 |

20.9 |

22.8 |

|||||||||||||||||

|

r |

Min |

0.6 |

0.8 |

0.8 |

0.8 |

1 |

1 |

1 |

1 |

1 |

1.2 |

1.2 |

1.6 |

1.6 |

|||||||||||||||||

|

s |

Max=Nominal |

27 |

30 |

32 |

36 |

41 |

46 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

|||||||||||||||||

|

A Class |

Min |

26.67 |

29.67 |

31.61 |

35.38 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|||||||||||||||||

|

B Class |

Min |

26.15 |

29.16 |

31 |

35 |

40 |

45 |

49 |

53.8 |

58.8 |

63.1 |

68.1 |

73.1 |

78.1 |

|||||||||||||||||

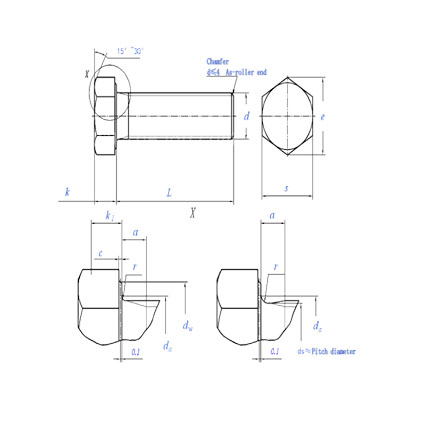

Detail drawing

HDG generally refers to hot-dip galvanizing. Hot-dip galvanizing is to make the molten metal react with the iron matrix to produce an alloy layer, so that the matrix and the coating are combined. Hot-dip galvanizing is to pickle the iron and steel parts first, in order to remove the iron oxide on the surface of the iron and steel parts, after pickling, it is cleaned in a tank of ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to the hot dip coating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

The corrosion resistance is mainly determined by the thickness of the galvanized layer, so the thickness measurement is often the main basis for judging the quality of the galvanized layer. The angle and speed of the solution also have a great influence. Therefore, it is practically impossible to obtain a completely uniform coating thickness. Therefore, the measurement of the adhesion amount can never be judged by a single point (location). It is only meaningful to measure the average adhesion weight (g) per unit area (㎡). There are many methods to measure the adhesion amount, such as destructive section metallographic observation method, pickling method, non-destructive film thickness meter method, electrochemical method, estimation method of weight difference between incoming and outgoing goods, etc. The commonly used methods are the film thickness gauge method and the pickling method.

Packing

We provide a variety of different packaging to meet different shipping environment and cost control. The most common types of packaging are ton packs, woven bags, boxes in bulk, boxes in boxes, plus pallets or wooden cases to meet sea or air transport requirements. Below are photos of the different packaging types we offer for reference.

About us

* The following diagram identifies the different trade incoterms. Please select the one you prefer.

Product detail pictures:

Related Product Guide:

Using a full scientific good quality administration system, very good quality and superior faith, we win good standing and occupied this discipline for OEM Manufacturer Fully Threaded Bolts - HDG DIN933 Hex Head Bolt Hot Dipped Galvanized – Hongji , The product will supply to all over the world, such as: Boston, Iran, Eindhoven, Now the competition in this field is very fierce; but we will still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. "Change for the better!" is our slogan, which means "A better world is before us, so let's enjoy it!" Change for the better! Are you ready?

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed