Manufacturer of Hex Head Bolt - DIN912 T2 Copper Hex Socket Cup Head Screw – Hongji

Manufacturer of Hex Head Bolt - DIN912 T2 Copper Hex Socket Cup Head Screw – Hongji

Manufacturer of Hex Head Bolt - DIN912 T2 Copper Hex Socket Cup Head Screw – Hongji Detail:

Description

QUICK Response

QUICK Quotation

QUICK Delivery

READY TO SHIP DELIVERY

10000+ SKU in warehouse

We Commit for RTS items:

70% items delivered within 5 days

80% items delivered within 7 days

90% items delivered within 10 days

Bulk orders, please contact customer service

|

d |

M1.4 |

M1.6 |

M2 |

M2.5 |

M3 |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

(M14) |

M16 |

(M18) |

M20 |

|

|

P |

Coarse thread |

0.3 |

0.35 |

0.4 |

0.45 |

0.5 |

0.7 |

0.8 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2 |

2.5 |

2.5 |

|

Fine thread |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

1 |

1.25 |

1.5 |

1.5 |

1.5 |

2 |

2 |

|

|

Very Fine thread |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

1 |

1.25 |

/ |

/ |

1.5 |

1.5 |

|

|

b |

Reference value |

14 |

15 |

16 |

17 |

18 |

20 |

22 |

24 |

28 |

32 |

36 |

40 |

44 |

48 |

52 |

|

dk |

Max (Smooth) |

2.6 |

3 |

3.8 |

4.5 |

5.5 |

7 |

8.5 |

10 |

13 |

16 |

18 |

21 |

24 |

27 |

30 |

|

Max (Knurl*) |

2.74 |

3.14 |

3.98 |

4.68 |

5.68 |

7.22 |

8.72 |

10.22 |

13.27 |

16.27 |

18.27 |

21.33 |

24.33 |

27.33 |

30.33 |

|

|

Min |

2.46 |

2.86 |

3.62 |

4.32 |

5.32 |

6.78 |

8.28 |

9.78 |

12.73 |

15.73 |

17.73 |

20.67 |

23.67 |

26.67 |

29.67 |

|

|

ds |

Max |

1.4 |

1.6 |

2 |

2.5 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

|

Min |

1.26 |

1.46 |

1.86 |

2.36 |

2.86 |

3.82 |

4.82 |

5.82 |

7.78 |

9.78 |

11.73 |

13.73 |

15.73 |

17.73 |

19.67 |

|

|

k |

Max |

1.4 |

1.6 |

2 |

2.5 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

|

Min |

1.26 |

1.46 |

1.86 |

2.36 |

2.86 |

3.82 |

4.82 |

5.7 |

7.64 |

9.64 |

11.57 |

13.57 |

15.57 |

17.57 |

19.48 |

|

|

s |

Nominal |

1.3 |

1.5 |

1.5 |

2 |

2.5 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

14 |

17 |

|

Min |

1.32 |

1.52 |

1.52 |

2.02 |

2.52 |

3.02 |

4.02 |

5.02 |

6.02 |

8.025 |

10.025 |

12.032 |

14.032 |

14.032 |

17.05 |

|

|

Max |

1.36 |

1.56 |

1.56 |

2.06 |

2.58 |

3.08 |

4.095 |

5.14 |

6.14 |

8.175 |

10.175 |

12.212 |

14.212 |

14.212 |

17.23 |

|

|

t |

Min |

0.6 |

0.7 |

1 |

1.1 |

1.3 |

2 |

2.5 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

Thread length=b |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

d |

(M22) |

M24 |

(M27) |

M30 |

(M33) |

M36 |

M42 |

M48 |

M56 |

M64 |

M72 |

M80 |

M90 |

M100 |

|

|

P |

Coarse thread |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4.5 |

5 |

5.5 |

6 |

6 |

6 |

6 |

6 |

|

Fine thread |

2 |

2 |

2 |

2 |

2 |

3 |

3 |

3 |

4 |

4 |

4 |

4 |

4 |

4 |

|

|

Very Fine thread |

1.5 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|

|

b |

Reference value |

56 |

60 |

66 |

72 |

78 |

84 |

96 |

108 |

124 |

140 |

156 |

172 |

192 |

212 |

|

dk |

Max (Smooth) |

33 |

36 |

40 |

45 |

50 |

54 |

63 |

72 |

84 |

96 |

108 |

120 |

135 |

150 |

|

Max (Knurl*) |

33.39 |

36.39 |

40.39 |

45.39 |

50.39 |

54.46 |

63.46 |

72.46 |

84.54 |

96.54 |

108.54 |

120.54 |

135.63 |

150.63 |

|

|

Min |

32.61 |

35.61 |

39.61 |

44.61 |

49.61 |

53.54 |

62.54 |

71.54 |

83.46 |

95.46 |

107.46 |

119.46 |

134.37 |

149.37 |

|

|

ds |

Max |

22 |

24 |

27 |

30 |

33 |

36 |

42 |

48 |

56 |

64 |

72 |

80 |

90 |

100 |

|

Min |

21.67 |

23.67 |

26.67 |

29.67 |

32.61 |

35.61 |

41.61 |

47.61 |

55.54 |

63.54 |

71.54 |

79.54 |

89.46 |

99.46 |

|

|

k |

Max |

22 |

24 |

27 |

30 |

33 |

36 |

42 |

48 |

56 |

64 |

72 |

80 |

90 |

100 |

|

Min |

21.48 |

23.48 |

26.48 |

29.48 |

32.38 |

35.38 |

41.38 |

47.38 |

56.26 |

63.26 |

71.26 |

79.26 |

89.13 |

99.13 |

|

|

s |

Nominal |

17 |

19 |

19 |

22 |

24 |

27 |

32 |

36 |

41 |

46 |

55 |

65 |

75 |

85 |

|

Min |

17.05 |

19.065 |

19.065 |

22.065 |

24.065 |

27.065 |

32.08 |

36.08 |

41.08 |

46.08 |

55.1 |

65.1 |

75.1 |

85.12 |

|

|

Max |

17.23 |

19.275 |

19.275 |

22.275 |

24.275 |

27.275 |

32.33 |

36.33 |

41.33 |

46.33 |

55.4 |

65.4 |

75.4 |

85.47 |

|

|

t |

Min |

11 |

12 |

13.5 |

15.5 |

18 |

19 |

24 |

28 |

34 |

38 |

43 |

48 |

54 |

60 |

|

Thread length=b |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

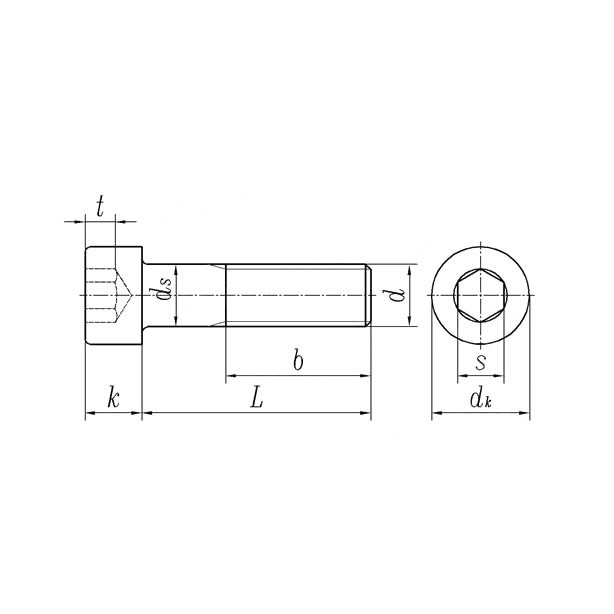

Detail drawing

What is the difference between Copper, Brass, Bronze?

Copper, Brass and Bronze, otherwise known as the “Red Metals”, may look the same initially. But they indeed have many difference in element, performance and so on.

Copper

Copper is used in a wide range of products due to its excellent electrical and thermal conductivity, good strength, good formability and resistance to corrosion. Pipe and pipe fittings are commonly manufactured from these metals due to their corrosion resistance. They can be readily soldered and brazed, and many can be welded by various gas, arc and resistance methods. They can be polished and buffed to almost any desired texture and luster.

There are grades of unalloyed Copper, and they can vary in the amount of impurities that are contained. Oxygen-free copper grades are used specifically in functions where high conductivity and ductility are needed.

One of the most important properties of copper is its ability to fight bacteria. After extensive antimicrobial testing by the Environmental Protection Agency, it was found that 355 copper alloys, including many brasses, were found to kill more than 99.9% of bacteria within two hours of contact. Normal tarnishing was found not to impair antimicrobial effectiveness.

Copper Applications

Copper was one of the earliest metals discovered. The Greeks and Romans made it into tools or adornments, and there are even historical details showing the application of copper to sterilize wounds and purify drinking water. Today it is most commonly found in electrical materials such as wiring because of its ability to effectively conduct electricity.

Brass

Brass is mainly an alloy that consists of copper with zinc added. Brasses can have varying amounts of zinc or other elements added. These varying mixtures produce a wide range of properties and variation in color. Increased amounts of zinc provide the material with improved strength and ductility. Brass can range in color from red to yellow depending on the amount of zinc added to the alloy.

If the zinc content of the brass ranges from 32% to 39%, it will have increased hot-working abilities but the cold-working will be limited.

If the brass contains over 39% zinc (example – Muntz Metal), it will have a higher strength and lower ductility (at room temperature).

Brass Applications

Brass is commonly used for decorative purposes primarily because of its resemblance to gold. It is also a commonly used to make musical instruments due to its high workability and durability.

Bronze

Bronze is an alloy that consists primarily of copper with the addition of other ingredients. In most cases the ingredient added is typically tin, but arsenic, phosphorus, aluminum, manganese, and silicon can also be used to produce different properties in the material. All of these ingredients produce an alloy much harder than copper alone.

Bronze is characterized by its dull-gold color. You can also tell the difference between bronze and brass because bronze will have faint rings on its surface.

Bronze Applications

Bronze is used in the construction of sculptures, musical instruments and medals, and in industrial applications such as bushings and bearings, where its low metal on metal friction is an advantage. Bronze also has nautical applications because of its resistance to corrosion.

Packing

About us

* The following diagram identifies the different trade incoterms. Please select the one you prefer.

Product detail pictures:

Related Product Guide:

In the past few years, our business absorbed and digested advanced technologies both equally at home and abroad. In the meantime, our company staffs a group of experts devoted to your advancement of Manufacturer of Hex Head Bolt - DIN912 T2 Copper Hex Socket Cup Head Screw – Hongji , The product will supply to all over the world, such as: Hyderabad, Mauritius, Philippines, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed