Factory Supply Screw Tnut - DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9 – Hongji

Factory Supply Screw Tnut - DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9 – Hongji

Factory Supply Screw Tnut - DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9 – Hongji Detail:

Description

QUICK Response

QUICK Quotation

QUICK Delivery

READY TO SHIP DELIVERY

10000+ SKU in warehouse

We Commit for RTS items:

70% items delivered within 5 days

80% items delivered within 7 days

90% items delivered within 10 days

Bulk orders, please contact customer service

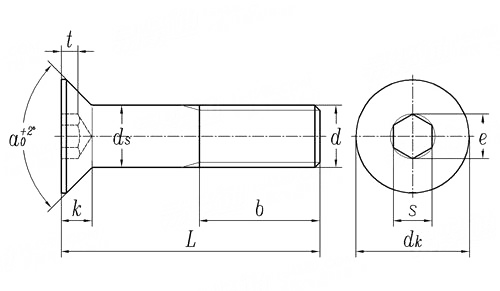

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Pitch | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | tol.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L>200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Max=Nominal | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Max=Nominal | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Nominal | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Max=Nominal | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Detail description

High strength fasteners will produce crispness when galvanized. Need special attention.

Hydrogen embrittlement is usually characterized by delayed fracture under stress. There have been automobile springs, washers, screws, sheet springs and other galvanized parts, in a few hours after assembly has been broken, the fracture proportion of 40% ~ 50%. In the process of using cadmium-plated parts of a special product, there was batch crack fracture, and a national key problem was solved and a strict dehydrogenation process was formulated. In addition, there are some hydrogen embrittlement does not show delayed fracture phenomenon, such as: electroplating hanger (steel wire, copper wire) due to many times of electroplating and pickling plating, hydrogen penetration is more serious, often appear in use a fold will occur brittle fracture phenomenon; The mandrel of a shotgun, after several times of chroming, fell to the ground and broke; Some quenched parts (large internal stress) will crack when pickling. These parts are severely hydrogenated and crack without external stress, which can no longer be used to restore the original toughness by dehydrogenation.

The higher the material strength, the greater the hydrogen embrittlement sensitivity. This is a basic concept that must be clarified by surface treatment technicians when compiling electroplating process specifications. Steels with tensile strength σb>105kg/mm2 required by international standards should be subjected to pre-plating stress and post-plating dehydrogenation treatment accordingly. The French aviation industry requires corresponding dehydrogenation treatment for steel parts with yield strength σs>90kg/mm2.

Due to the good correspondence between steel strength and hardness, it is more intuitive and convenient to judge the hydrogen embrittlement sensitivity of material by hardness than by strength. Because a perfect product drawing and machining process should be marked with steel hardness. In the electroplating, we found that the hardness of steel around HRC38 began to show the risk of hydrogen embrittlement fracture. For parts higher than HRC43, dehydrogenation should be considered after plating. When the hardness is about HRC60, dehydrogenation treatment must be carried out immediately after surface treatment, otherwise the steel parts will crack within a few hours.

Packing

About us

* The following diagram identifies the different trade incoterms. Please select the one you prefer.

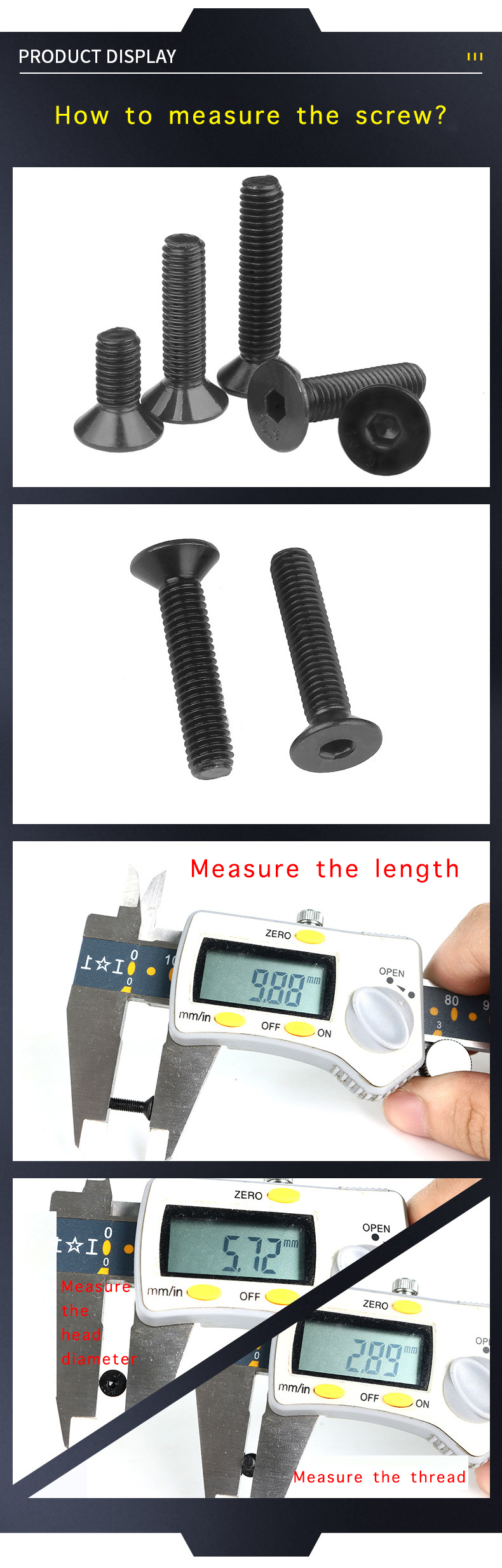

Product detail pictures:

Related Product Guide:

We will devote ourselves to providing our esteemed customers with the most enthusiastically thoughtful services for Factory Supply Screw Tnut - DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9 – Hongji , The product will supply to all over the world, such as: Armenia, Somalia, Slovak Republic, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed